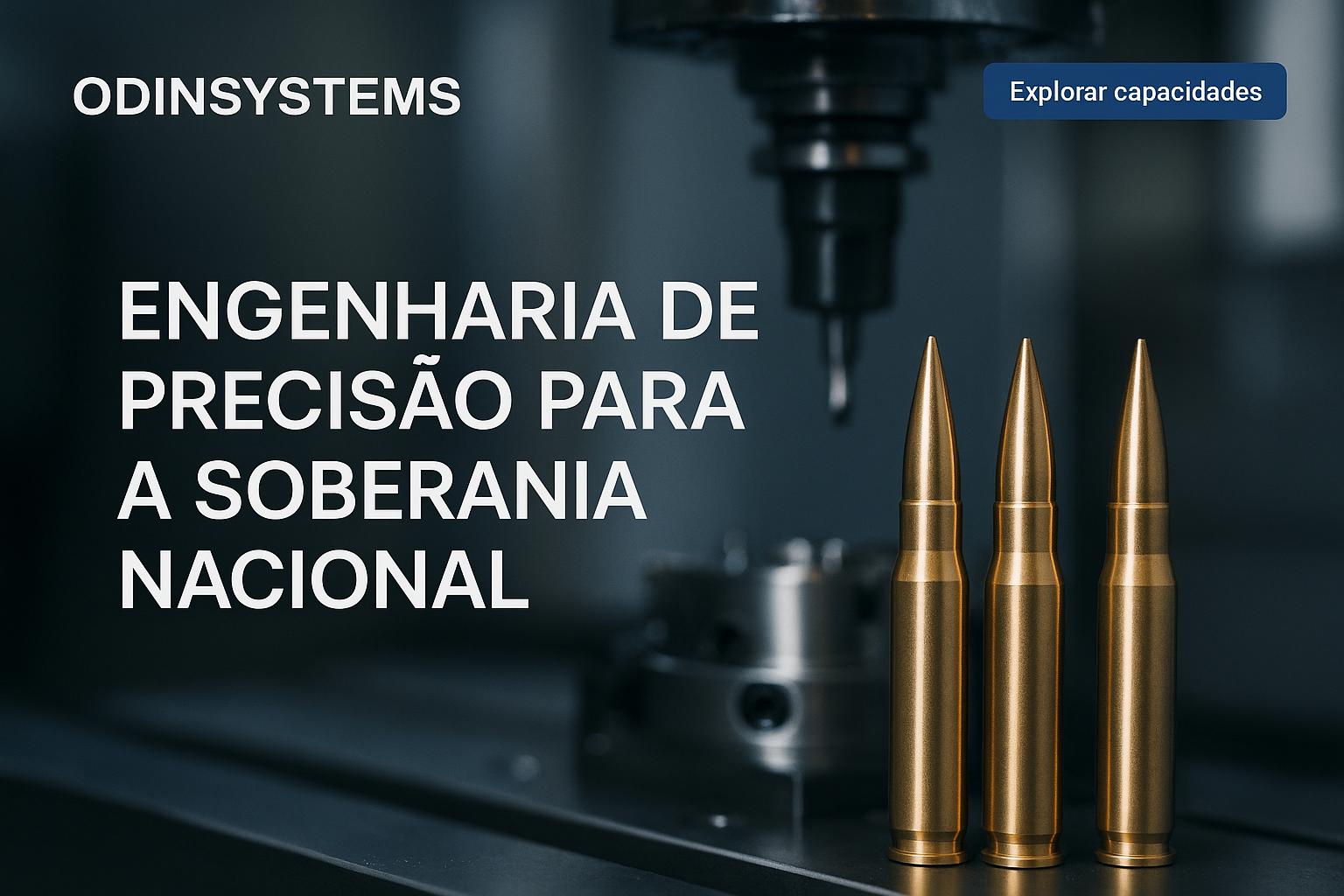

Excelência em soluções metálicas de defesa.

"Na ODIN SYSTEMS, somos especializados na fabricação de produtos metálicos de alta qualidade para o setor da defesa e indústria, fornecendo soluções confiáveis e inovadoras para nossos clientes."

Conheça a ODIN SYSTEMS" Conheça a ODIN SYSTEMS - Fabricação de Produtos Metálicos de Excelência A ODIN SYSTEMS é uma empresa especializada na fabricação de produtos metálicos para diversos segmentos, com destaque para o setor da defesa e indústria. Com uma equipe altamente qualificada e tecnologia de ponta, garantimos a excelência em cada etapa do processo produtivo.

A ODIN SYSTEMS é uma empresa especializada na fabricação de produtos metálicos para o setor da defesa e indústria. Com anos de experiência e qualidade, somos reconhecidos como líderes no mercado. Confie em nós para fornecer soluções eficientes e inovadoras para o seu negócio.

"Defesa com qualidade" Bem-vindo à ODIN SYSTEMS, uma empresa especializada em fabricação de produtos metálicos no setor da defesa. Nosso foco é fornecer soluções de alta qualidade e confiabilidade para nossos clientes, garantindo sua segurança e proteção.

A ODIN SYSTEMS é uma empresa especializada na fabricação de produtos metálicos para o setor da defesa e indústria. Com anos de experiência e tecnologia avançada, oferecemos soluções eficientes e de alta qualidade para as necessidades dos nossos clientes. Entre em contato conosco e descubra como podemos ajudar o seu negócio a crescer.

1. Design de produtos personalizados

Design de produtos personalizados é a criação de itens exclusivos e únicos, feitos sob medida para atender às necessidades e preferências específicas de cada cliente. Esses produtos são projetados com foco no estilo, funcionalidade e personalidade do consumidor, levando em consideração suas preferências de cores, materiais, estilos e até mesmo detalhes personalizados, como monogramas e logotipos. O processo de design de produtos personal

2. Fabricação de protótipos rápidos

A fabricação de protótipos rápidos é um processo de produção de modelos iniciais de produtos, com o objetivo de testar e validar suas funcionalidades e design antes de iniciar a produção em massa. Esses protótipos são criados de forma rápida e eficiente, utilizando tecnologias como a impressão 3D, usinagem CNC e moldagem por injeção. Esse processo permite que os projetos sejam

3. Consultoria em engenharia de materiais

A consultoria em engenharia de materiais é um serviço especializado que tem como objetivo auxiliar empresas e profissionais na seleção, desenvolvimento e aplicação de materiais em seus projetos. Com base em conhecimentos técnicos e científicos, a consultoria oferece soluções customizadas para atender às necessidades específicas de cada cliente. Os consultores em engenharia de materiais possuem expertise em áreas como metalurgia, cer

Defesa em Metal

A ODIN SYSTEMS é uma empresa de fabricação de produtos metálicos especializada no setor da defesa e indústria. Com tecnologia avançada e compromisso com a qualidade, fornecemos soluções inovadoras e confiáveis para nossos clientes.

Conheça a ODIN SYSTEMS" A ODIN SYSTEMS é uma empresa especializada na fabricação de produtos metálicos, com foco no setor da defesa e indústria. Com uma equipe altamente qualificada e tecnologia de ponta, oferecemos soluções inovadoras e de alta qualidade para atender às necessidades de nossos clientes.

A nossa galeria de fotos apresenta os nossos produtos metálicos de alta qualidade e tecnologia avançada. Confira as nossas instalações modernas e a excelência em cada detalhe de nossos produtos. Veja como a ODIN SYSTEMS é referência no setor da defesa e indústria.

Contacto

Bem-vindo à ODIN SYSTEMS, uma empresa especializada na fabricação de produtos metálicos para o setor da defesa e indústria.

ODIN SYSTEMS

Rua do Ouro 797, 4150-555 Porto